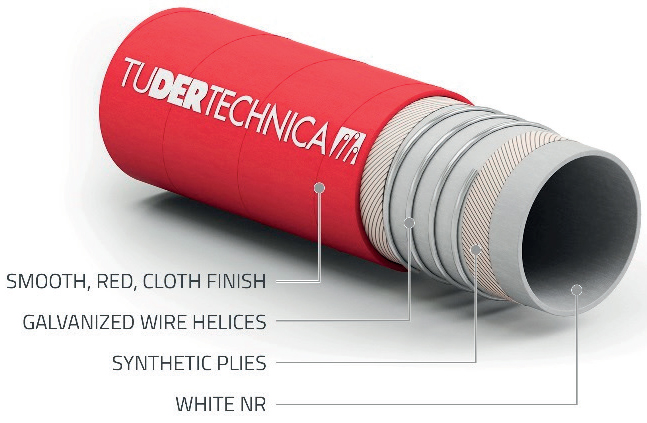

Suction and delivery hose suitable for milk, milk by-products, wine and non-fatty food products.

DESCRIPTION

- Tube : NR, white, phthalates free, tested in compliance with 1907 / 2006 / CE (REACH). Meets FDA 21 CFR 177.2600, BFR recommendation XXI cat 2, DM 21. 03. 73 e seguenti, EUROPEAN REGLEMENT 1935 / 2004 / CE, JAPAN-Ministry of Health and Welfare Notice No. 370, 1959 and No. 201, 2006.

- Reinforcement : synthetic plies, galvanized wire helices

- Cover : smooth, red, abrasion, ageing and ozone resistant, cloth finish

- Marking : TUDERTECHNICA TUFOOD® NATURAL

TECHNICAL CHARACTERISTICS

- Temperature range : -40°C / +80°C ( -40°F / +176°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 19 | 0,75 | 31 | 1,22 | 0,9 | 13 | 10 | 150 | 30 | 450 | 0,66 | 0,44 | 60 | 2,36 |

| 25 | 1,00 | 37 | 1,46 | 0,9 | 13 | 10 | 150 | 30 | 450 | 0,81 | 0,54 | 85 | 3,35 |

| 32 | 1,25 | 44 | 1,73 | 0,9 | 13 | 10 | 150 | 30 | 450 | 1,00 | 0,67 | 115 | 4,53 |

| 38 | 1,50 | 51 | 2,00 | 0,9 | 13 | 10 | 150 | 30 | 450 | 1,28 | 0,86 | 150 | 5,91 |

| 51 | 2,00 | 64 | 2,52 | 0,9 | 13 | 10 | 150 | 30 | 450 | 1,66 | 1,11 | 210 | 8,27 |

| 63,5 | 2,50 | 78,5 | 3,09 | 0,9 | 13 | 10 | 150 | 30 | 450 | 2,52 | 1,69 | 265 | 10,43 |

| 76 | 3,00 | 91 | 3,58 | 0,9 | 13 | 10 | 150 | 30 | 450 | 2,97 | 1,99 | 320 | 12,60 |

| 120 | 4,00 | 118 | 4,65 | 0,9 | 13 | 10 | 150 | 30 | 450 | 4,16 | 2,79 | 430 | 6,93 |

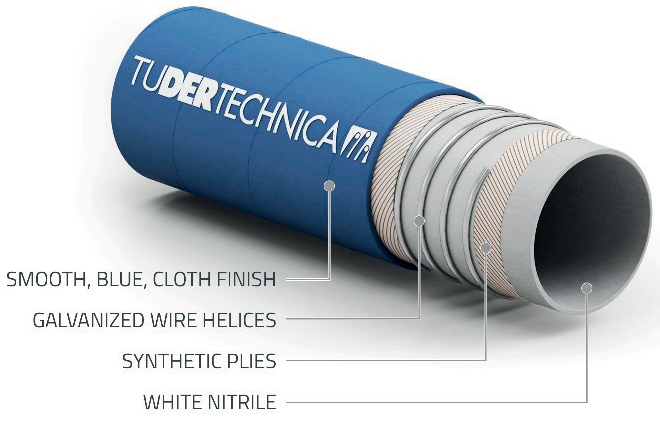

Suction and delivery hose suitable for fatty and non-fatty food products.

DESCRIPTION

- Tube : NBR, white, phthalates free, tested in compliance with 1907 / 2006 / CE (REACH). Meets FDA 21 CFR 177.2600, BFR recommendation XXI cat 2, DM 21.03.73 e seguenti, EUROPEAN REGLEMENT 1935 / 2004 / CE, JAPAN-Ministry of Health and Welfare Notice No. 370, 1959 and No. 201, 2006, 3A Sanitary Standard Class II.

- Reinforcement : synthetic plies, galvanized wire helices

- Cover : smooth, blue, abrasion, ageing, ozone and oil resistant, cloth finish

- Marking : TUDERTECHNICA TUFOOD® FAT

TECHNICAL CHARACTERISTICS

- Temperature range : -25°C / +80°C ( -13°F / +176°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | ||||||||

[mm] |

[in] |

[mm] |

[in] |

[bar] |

[psi] |

[bar] |

[psi] |

[bar] |

[psi] |

[kg/mt] |

[lbs/ft] |

[mm] |

[in] |

|

19 |

0,75 |

31 |

1,22 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,74 |

0,50 |

60 |

2,36 |

|

25 |

1,00 |

37 |

1,46 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,91 |

0,61 |

85 |

3,35 |

|

32 |

1,25 |

44 |

1,73 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,12 |

0,75 |

115 |

4,53 |

|

38 |

1,50 |

51 |

2,00 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,40 |

0,94 |

150 |

5,91 |

|

51 |

2,00 |

64 |

2,52 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,80 |

1,21 |

210 |

8,27 |

|

63,5 |

2,50 |

78,5 |

3,09 |

0,9 |

13 |

10 |

150 |

30 |

450 |

2,70 |

1,81 |

265 |

10,43 |

|

76 |

3,00 |

91 |

3,58 |

0,9 |

13 |

10 |

150 |

30 |

450 |

3,17 |

2,12 |

320 |

12,60 |

|

102 |

4,00 |

118 |

4,65 |

0,9 |

13 |

10 |

150 |

30 |

450 |

4,42 |

2,96 |

430 |

16,93 |

|

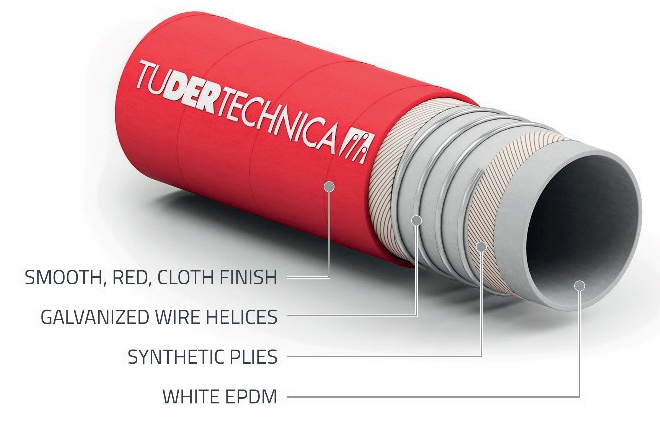

Suction and delivery hose suitable for a wide range of food products. Not recommended for fatty food products and oil.

DESCRIPTION

- Tube : EPDM, white, phthalates free, tested in compliance with 1907 / 2006 / CE (REACH). Meets FDA 21 CFR 177.2600, BFR recommendation XXI cat 2, DM 21.03.73 e seguenti, EUROPEAN REGLEMENT 1935 / 2004 / CE, JAPAN-Ministry of Health and Welfare Notice No. 370, 1959 and No. 201, 2006, 3A Sanitary Standard Class II.

- Reinforcement : synthetic plies, galvanized wire helices

- Cover : smooth, red, abrasion, ageing and ozone resistant, cloth finish

- Marking : TUDERTECHNICA TUFOOD® EPDM

TECHNICAL CHARACTERISTICS

- Temperature range : -40°C / +120°C ( -40°F / +248°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

[mm] |

[in] |

[mm] |

[in] |

[bar] |

[psi] |

[bar] |

[psi] |

[bar] |

[psi] |

[kg/mt] |

[lbs/ft] |

[mm] |

[in] |

19 |

0,75 |

31 |

1,22 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,70 |

0,47 |

60 |

2,36 |

25 |

1,00 |

37 |

1,46 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,85 |

0,57 |

85 |

3,35 |

32 |

1,25 |

44 |

1,73 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,04 |

0,70 |

115 |

4,53 |

38 |

1,50 |

51 |

2,00 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,31 |

0,88 |

150 |

5,91 |

51 |

2,00 |

64 |

2,52 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,69 |

1,13 |

210 |

8,27 |

63,5 |

2,50 |

78,5 |

3,09 |

0,9 |

13 |

10 |

150 |

30 |

450 |

2,55 |

1,71 |

265 |

10,43 |

76 |

3,00 |

91 |

3,58 |

0,9 |

13 |

10 |

150 |

30 |

450 |

2,99 |

2,00 |

320 |

12,60 |

102 |

4,00 |

118 |

4,65 |

0,9 |

13 |

10 |

150 |

30 |

450 |

4,18 |

2,80 |

430 |

16,93 |

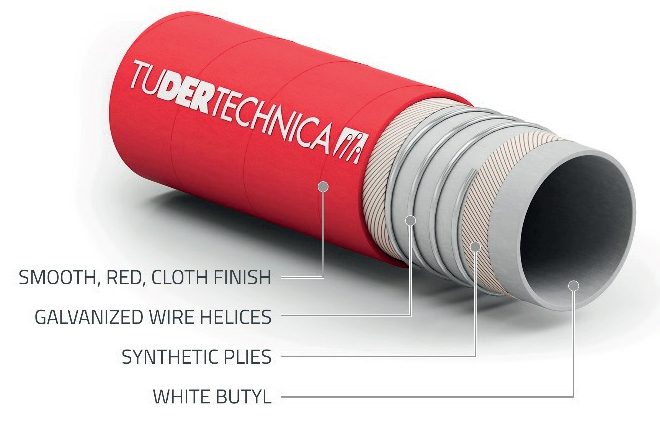

Premium grade low permeation suction and delivery hose suitable for a wide range of products. Recommended for wine and spirits.

DESCRIPTION

- Tube : IIR, white, phthalates free, tested in compliance with 1907 / 2006 / CE (REACH). Meets FDA 21 CFR 177.2600, DM 21.03.73 e seguenti, EUROPEAN REGLEMENT 1935 / 2004 / CE, JAPAN-Ministry of Health and Welfare Notice No. 370, 1959 and No. 201, 2006, 3A Sanitary Standard Class II

- Reinforcement : synthetic plies, galvanized wire helices

- Cover : smooth, red, abrasion, ageing and ozone resistant, cloth finish

- Marking : TUDERTECHNICA TUPRESTIGE

TECHNICAL CHARACTERISTICS

- Temperature range : -40°C / +120°C ( -40°F / +248°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||||

[mm] |

[in] |

[mm] |

[in] |

[bar] |

[psi] |

[bar] |

[psi] |

[bar] |

[psi] |

[kg/mt] |

[lbs/ft] |

[mm] |

[in] |

||

19 |

0,75 |

31 |

1,22 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,71 |

0,48 |

60 |

2,36 |

||

25 |

1,00 |

37 |

1,46 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,87 |

0,58 |

85 |

3,35 |

||

32 |

1,25 |

44 |

1,73 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,06 |

0,71 |

115 |

4,53 |

||

38 |

1,50 |

51 |

2,00 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,34 |

0,90 |

150 |

5,91 |

||

51 |

2,00 |

64 |

2,52 |

0,9 |

13 |

10 |

150 |

30 |

450 |

1,72 |

1,15 |

210 |

8,27 |

||

63,5 |

2,50 |

78,5 |

3,09 |

0,9 |

13 |

10 |

150 |

30 |

450 |

2,59 |

1,74 |

265 |

10,43 |

||

76 |

3,00 |

91 |

3,58 |

0,9 |

13 |

10 |

150 |

30 |

450 |

3,04 |

2,04 |

320 |

12,60 |

||

102 |

4,00 |

118 |

4,65 |

0,9 |

13 |

10 |

150 |

30 |

450 |

4,25 |

2,85 |

430 |

16,93 |

||

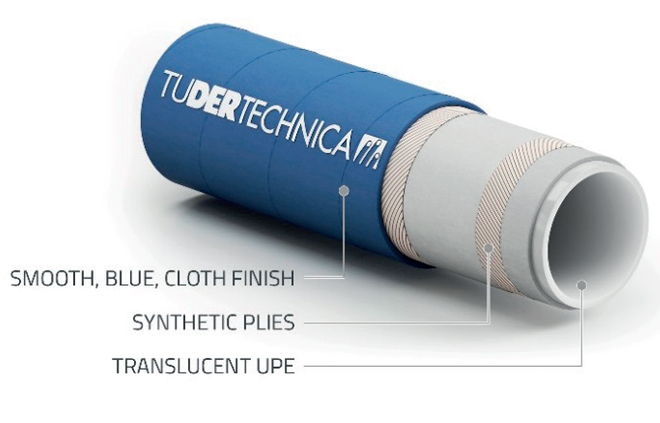

Delivery hose suitable for potable water.

DESCRIPTION

- Tube : UPE, translucent, phthalates free, tested in compliance with 1907/2006/CE (REACH). Meets FDA 21 CFR 177.1520, BfR CAT III, DM 21.03.73 e seguenti, KTW and W270, EUROPEAN REGLEMENT 1935/2004/CE, AND 10/2011/CE, JAPAN-Ministry of Health and Welfare Notice No.370,1959 and No.201, 2006

- Reinforcement : synthetic plies

- Cover : smooth, blue, abrasion, ageing and ozone resistant, cloth finish

- Marking : TUDERTECHNICA TUACQUA / KTW

TECHNICAL CHARACTERISTICS

- Temperature range : -35°C / +100°C ( -31°F / +212°F)

- Norm : ISO 1307 for dimensional tolerances KTW class A -35°C / +55°C ( -31°F / +131°F)

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||||

[mm] |

[in] |

[mm] |

[in] |

[bar] |

[psi] |

[bar] |

[psi] |

[bar] |

[psi] |

[kg/mt] |

[lbs/ft] |

[mm] |

[in] |

||

10 |

0,39 |

17,5 |

0,69 |

- |

- |

20 |

300 |

60 |

900 |

0,21 |

0,14 |

50 |

1,97 |

||

13 |

0,50 |

21,5 |

0,85 |

- |

- |

20 |

300 |

60 |

900 |

0,30 |

0,20 |

65 |

2,56 |

||

16 |

0,63 |

26 |

1,02 |

- |

- |

20 |

300 |

60 |

900 |

0,43 |

0,29 |

80 |

3,15 |

||

19 |

0,75 |

29 |

1,14 |

- |

- |

20 |

300 |

60 |

900 |

0,49 |

0,33 |

95 |

3,74 |

||

25 |

1,00 |

35 |

1,38 |

- |

- |

20 |

300 |

60 |

900 |

0,62 |

0,42 |

140 |

5,51 |

||

32 |

1,25 |

45 |

1,77 |

- |

- |

20 |

300 |

60 |

900 |

1,06 |

0,71 |

190 |

7,48 |

||

38 |

1,50 |

52 |

2,05 |

- |

- |

20 |

300 |

60 |

900 |

1,35 |

0,90 |

230 |

9,06 |

||

40 |

1,57 |

54 |

2,13 |

- |

- |

20 |

300 |

60 |

900 |

1,39 |

0,93 |

245 |

9,65 |

||

50 |

1,97 |

66 |

2,60 |

|

|

20 |

300 |

60 |

900 |

1,94 |

1,30 |

310 |

12,20 |

||

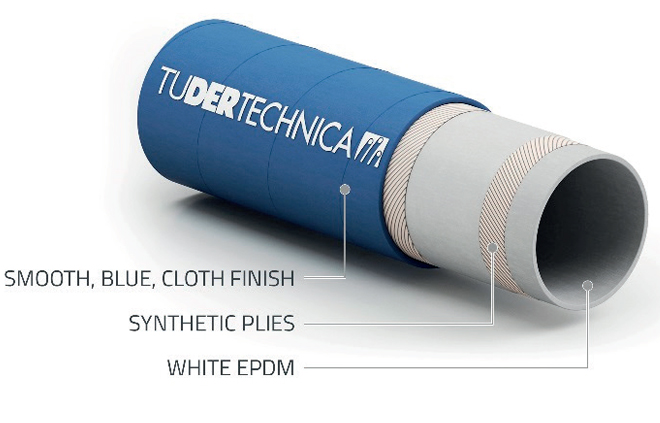

Delivery hose suitable for cleaning plant and equipment with hot water mixed with steam.

DESCRIPTION

- Tube : EPDM, white, phthalates free, tested in compliance with 1907/2006/CE (REACH). Meets FDA 21 CFR 177.2600, BFR recommendation XXI cat 2, DM 21.03.73 e seguenti, EUROPEAN REGLEMENT 1935/2004/CE, JAPAN-Ministry of Health and Welfare Notice No.370,1959 and No.201,2006, 3A Sanitary Standard Class II.

- Reinforcement : synthetic plies

- Cover : smooth, blue, abrasion, ageing, ozone and oil resistant, pin pricked, cloth finish

- Marking : TUDERTECHNICA TUBLUESTREAM

TECHNICAL CHARACTERISTICS

- Temperature range : -40°C / +164°C ( -40°F / +327°F) The operating temperature of the hose is directly dependent upon the specific fluid been conveyed, the length of time the fluid is in contact with the hose and the working pressure.

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Working Pressure (164°C) |

Working Pressure (95°C) |

Burst pressure | Appr. weight | Bending radius | |||||||

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 10 | 0,39 | 20 | 0,79 | 6 | 90 | 20 | 300 | 60 | 900 | 0,29 | 0,19 | - | - |

| 13 | 0,50 | 23 | 0,91 | 6 | 90 | 20 | 300 | 60 | 900 | 0,35 | 0,23 | - | - |

| 16 | 0,63 | 26 | 1,02 | 6 | 90 | 20 | 300 | 60 | 900 | 0,41 | 0,27 | - | - |

| 19 | 0,75 | 31 | 1,22 | 6 | 90 | 20 | 300 | 60 | 900 | 0,60 | 0,40 | - | - |

| 25 | 1,00 | 39,5 | 1,56 | 6 | 90 | 20 | 300 | 60 | 900 | 0,93 | 0,62 | - | - |

| 32 | 1,25 | 46,5 | 1,83 | 6 | 90 | 20 | 300 | 60 | 900 | 1,16 | 0,78 | - | - |

| 38 | 1,50 | 54 | 2,13 | 6 | 90 | 20 | 300 | 60 | 900 | 1,47 | 0,98 | - | - |

| 51 | 2,00 | 68 | 2,68 | 6 | 90 | 20 | 300 | 60 | 900 | 2,03 | 1,36 | - | - |

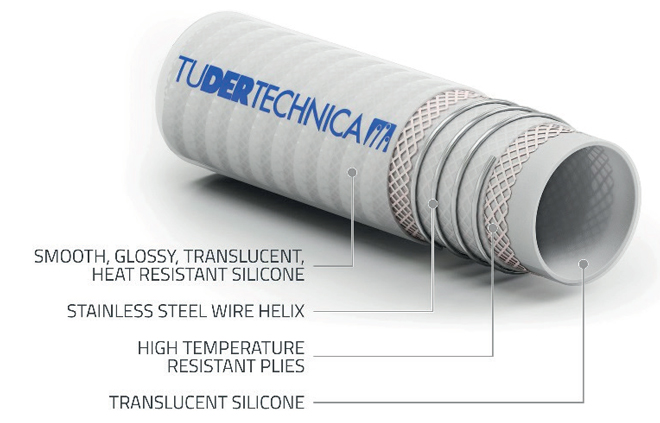

Suction and delivery hose suitable for cosmetic, pharmaceutical and food products. Meets migration test according to BfR Recommendation XV & XXI Cat. 2. Not intended for use as an implant material. Not suitable for blood or human fluids.

DESCRIPTION

- Tube : silicone, translucent, phthalates free, tested in compliance with 1907/2006/CE (REACH). Meets FDA CFR 21 PART 177.2600, USP XXXII class VI requirements, European Pharmacopoeia 3.1.9 Ed. VII 2011, ISO 10993 Sections 5,10,11:2009, BfR Recommendation XV & XXI Cat. 2, European Reglement 1935/2004/CE, DM 21/03/1973 e seguenti, Japan Ministry of Health and Welfare Notice No.370,1959, No.201,2006 and revision 2012, 3A Sanitary Standard Class II

- Reinforcement : high temperature resistant plies, stainless steel wire helix

- Cover : smooth, silicone, translucent, heat, ageing, ozone and abrasion resistant, glossy cover

- Marking : TUDERTECHNICA TUSIL® BRIGHT

TECHNICAL CHARACTERISTICS

- Temperature range : -60°C / +200°C ( -76°F / +392°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||||

[mm] |

[in] |

[mm] |

[in] |

[bar] |

[psi] |

[bar] |

[psi] |

[bar] |

[psi] |

[kg/mt] |

[lbs/ft] |

[mm] |

[in] |

||

13 |

0,50 |

24 |

0,94 |

0,9 |

13 |

15 |

225 |

45 |

675 |

0,46 |

0,31 |

60 |

2,36 |

||

16 |

0,63 |

27 |

1,06 |

0,9 |

13 |

14 |

210 |

42 |

630 |

0,53 |

0,36 |

70 |

2,76 |

||

19 |

0,75 |

30 |

1,18 |

0,9 |

13 |

13 |

195 |

39 |

585 |

0,60 |

0,40 |

80 |

3,15 |

||

25 |

1,00 |

36 |

1,42 |

0,9 |

13 |

10 |

150 |

30 |

450 |

0,73 |

0,49 |

100 |

3,94 |

||

32 |

1,25 |

43 |

1,69 |

0,9 |

13 |

8 |

120 |

24 |

360 |

0,89 |

0,60 |

130 |

5,12 |

||

38 |

1,50 |

51 |

2,00 |

0,9 |

13 |

7 |

105 |

21 |

315 |

1,21 |

0,81 |

155 |

6,10 |

||

51 |

2,00 |

64 |

2,52 |

0,9 |

13 |

6 |

90 |

18 |

270 |

1,56 |

1,05 |

210 |

8,27 |

||

63,5 |

2,50 |

78,5 |

3,09 |

0,9 |

13 |

5 |

75 |

15 |

225 |

2,32 |

1,55 |

260 |

10,24 |

||

76 |

3,00 |

91 |

3,58 |

0,9 |

13 |

4 |

60 |

12 |

180 |

2,72 |

1,82 |

310 |

12,20 |

||

102 |

4,00 |

117 |

4,61 |

0,9 |

13 |

3 |

45 |

9 |

135 |

3,55 |

2,38 |

420 |

16,54 |

||

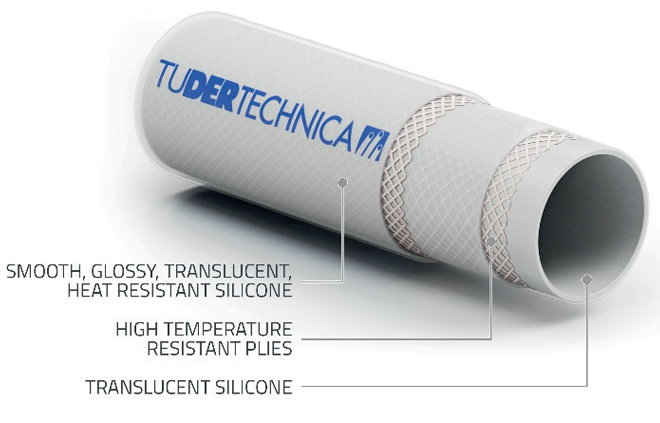

Delivery hose suitable for cosmetic, pharmaceutical and food products. Meets migration test according to BfR Recommendation XV & XXI Cat. 2. Not intended for use as an implant material. Not suitable for blood or human fluids.

DESCRIPTION

- Tube : silicone, translucent, phthalates free, tested in compliance with 1907 / 2006 / CE (REACH). Meets FDA CFR 21 PART 177.2600, USP XXXII class VI requirements, European Pharmacopoeia 3.1.9 Ed. VII 2011, ISO 10993 Sections 5,10,11 : 2009, BfR Recommendation XV & XXI Cat. 2, European Reglement 1935 / 2004 / CE, DM 21 / 03 / 1973 e seguenti, Japan Ministry of Health and Welfare Notice No. 370, 1959, No.201,2006 and revision 2012, 3A Sanitary Standard Class II

- Reinforcement : high temperature resistant plies

- Cover : smooth, silicone, translucent, heat, ageing, ozone and abrasion resistant, glossy cover

- Marking : TUDERTECHNICA TUSIL® BRIGHT

TECHNICAL CHARACTERISTICS

- Temperature range : -60°C / +200°C ( -76°F / +392°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

[mm] |

[in] |

[mm] |

[in] |

[bar] |

[psi] |

[bar] |

[psi] |

[bar] |

[psi] |

[kg/mt] |

[lbs/ft] |

[mm] |

[in] |

10 |

0,39 |

22 |

0,87 |

- |

- |

16 |

250 |

48 |

750 |

0,35 |

0,23 |

- |

- |

13 |

0,50 |

25 |

1,00 |

- |

- |

15 |

225 |

45 |

675 |

0,41 |

0,27 |

- |

- |

16 |

0,63 |

28 |

1,10 |

- |

- |

14 |

210 |

42 |

630 |

0,48 |

0,32 |

- |

- |

19 |

0,75 |

31 |

1,22 |

- |

- |

13 |

195 |

39 |

585 |

0,55 |

0,37 |

- |

- |

25 |

1,00 |

37 |

1,46 |

- |

- |

10 |

150 |

30 |

450 |

0,68 |

0,46 |

- |

- |

32 |

1,25 |

44 |

1,73 |

- |

- |

8 |

120 |

24 |

360 |

0,83 |

0,56 |

- |

- |

38 |

1,50 |

50 |

1,97 |

- |

- |

7 |

105 |

21 |

315 |

0,96 |

0,64 |

- |

- |

51 |

2,00 |

63 |

2,48 |

- |

- |

6 |

90 |

18 |

270 |

1,24 |

0,83 |

- |

- |

63,5 |

2,50 |

76,5 |

3,01 |

- |

- |

5 |

75 |

15 |

225 |

1,68 |

1,13 |

- |

- |

76 |

3,00 |

89 |

3,50 |

- |

- |

4 |

60 |

12 |

180 |

1,98 |

1,33 |

- |

- |

102 |

4,00 |

115 |

4,53 |

- |

- |

3 |

45 |

9 |

135 |

2,61 |

1,75 |

- |

- |