Suction and delivery hose designed according to EN 12115 standards for oil and petrol, aromatic content up to 50%. Tested and certified hose by INERIS for use in Atex area (Ex-Zone).

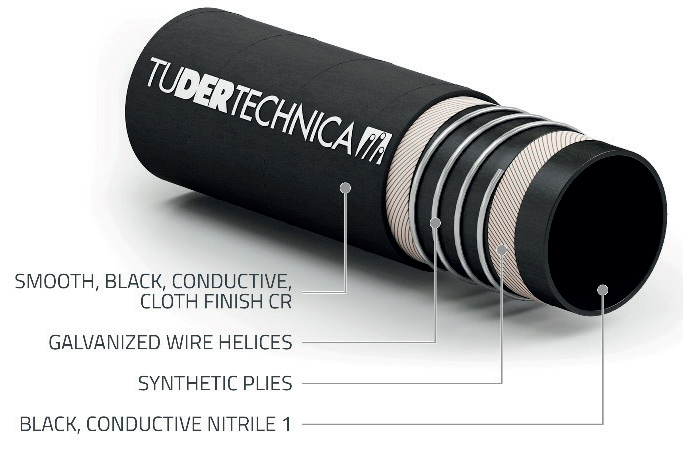

DESCRIPTION

- Tube : NBR 1, black, conductive

- Reinforcement : synthetic plies, galvanized wire helices, a/s copper wire to discharge static electricity

- Cover : smooth, CR, black, conductive, abrasion, ageing, ozone and oil resistant, cloth finish

- Marking : yellow tape TUDERTECHNICA TUPETROL MASTER embossed according to norm EN 12115 TUDERTECHNICA NBR1 EN12115:2011 DN SD PN 16 BAR Ω/T Q/Y

TECHNICAL CHARACTERISTICS

- Temperature range : -30°C / +100°C ( -22°F / +212°F) The operating temperature of the hose is directly dependent upon the specific fluid been conveyed and the length of time the fluid is in contact with the hose.

- Electrical properties : type Ω / T according to norm EN 12115 (R<106 Ω, R<109 Ω through the hose wall)

- Norm : EN12115 - TRbF 131/2

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 19 | 0,75 | 31 | 1,22 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 0,69 | 0,46 | 65 | 2,56 |

| 25 | 1,00 | 37 | 1,46 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 0,85 | 0,57 | 90 | 3,54 |

| 32 | 1,25 | 44 | 1,73 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 1,06 | 0,71 | 120 | 4,72 |

| 38 | 1,50 | 51 | 2,00 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 1,42 | 0,95 | 155 | 6,10 |

| 50 | 1,97 | 66 | 2,60 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 2,19 | 1,47 | 215 | 8,46 |

| 51 | 2,00 | 67 | 2,64 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 2,22 | 1,49 | 215 | 8,46 |

| 63,5 | 2,50 | 79,5 | 3,13 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 3,05 | 2,04 | 275 | 10,83 |

| 75 | 2,95 | 91 | 3,58 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 3,54 | 2,37 | 330 | 12,99 |

| 76 | 3,00 | 92 | 3,62 | 0,9 | 13 | 16 | 250 | 64 | 1000 | 3,58 | 2,40 | 330 | 12,99 |

| 100 | 3,94 | 116 | 4,57 | 0,9 | 13 | 12 | 185 | 48 | 750 | 4,58 | 3,07 | 450 | 17,72 |

| 102 | 4,00 | 118 | 4,65 | 0,9 | 13 | 12 | 185 | 48 | 750 | 4,64 | 3,11 | 450 | 17,72 |

Suction and delivery hose designed according to EN 12115 standards for oil and petrol, aromatic content up to 50%. Tested and certified hose by INERIS for use in Atex area (Ex-Zone).

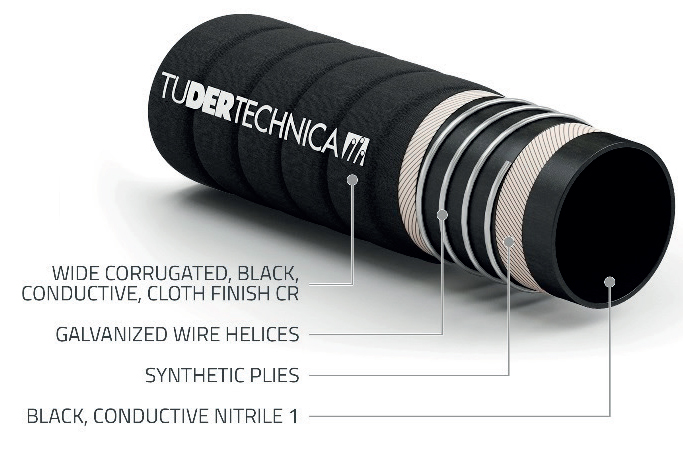

DESCRIPTION

- Tube : NBR 1, black, conductive

- Reinforcement : synthetic plies, galvanized wire helices, a/s copper wire to discharge static electricity

- Cover :wide corrugated, CR, black, conductive, abrasion, ageing, ozone and oil resistant, cloth finish

- Marking : yellow tape TUDERTECHNICA TUWAGON MASTER embossed according to norm EN 12115 TUDERTECHNICA NBR1 EN12115:2011 DN SD PN 10 BAR Ω/T Q/Y

TECHNICAL CHARACTERISTICS

- Temperature range :-30°C / +100°C ( -22°F / +212°F) The operating temperature of the hose is directly dependent upon the specific fluid been conveyed and the length of time the fluid is in contact with the hose.

- Electrical properties : type Ω/T according to norm EN 12115 (R<106 Ω, R<109 Ω through the hose wall)

- Norm : EN12115 - TRbF 131/2

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 32 | 1,25 | 44 | 1,73 | 0,9 | 13 | 10 | 150 | 40 | 600 | 1,18 | 0,79 | 100 | 3,94 |

| 38 | 1,50 | 51 | 2,00 | 0,9 | 13 | 10 | 150 | 40 | 600 | 1,39 | 0,93 | 125 | 4,92 |

| 50 | 1,97 | 66 | 2,60 | 0,9 | 13 | 10 | 150 | 40 | 600 | 2,10 | 1,41 | 180 | 7,09 |

| 51 | 2,00 | 67 | 2,64 | 0,9 | 13 | 10 | 150 | 40 | 600 | 2,13 | 1,43 | 180 | 7,09 |

| 63,5 | 2,50 | 79,5 | 3,13 | 0,9 | 13 | 10 | 150 | 40 | 600 | 2,71 | 1,82 | 230 | 9,06 |

| 75 | 2,95 | 91 | 3,58 | 0,9 | 13 | 10 | 150 | 40 | 600 | 3,18 | 2,13 | 280 | 11,02 |

| 76 | 3,00 | 92 | 3,62 | 0,9 | 13 | 10 | 150 | 40 | 600 | 3,22 | 2,16 | 280 | 11,02 |

| 100 | 3,94 | 116 | 4,57 | 0,9 | 13 | 10 | 150 | 40 | 600 | 4,41 | 2,95 | 400 | 15,75 |

| 102 | 4,00 | 118 | 4,65 | 0,9 | 13 | 10 | 150 | 40 | 600 | 4,46 | 2,99 | 400 | 15,75 |

Light and flexible lorry collecting hose suitable for oil and petrol, aromatic content up to 50%.

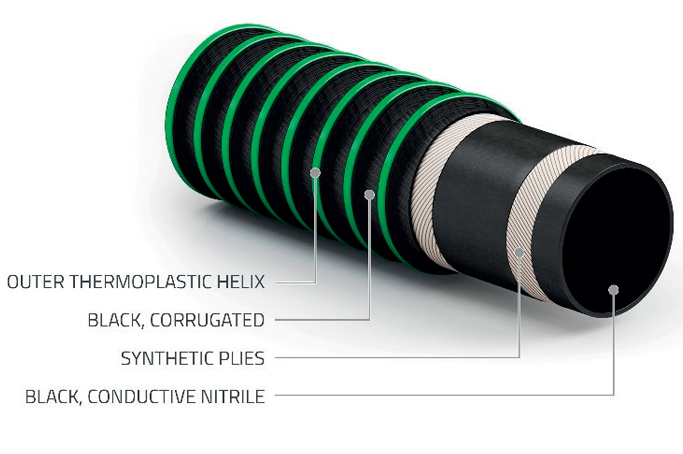

DESCRIPTION

- Tube : NBR, black, conductive

- Reinforcement : synthetic plies, a/s copper wire to discharge static electricity

- Cover : corrugated, black, abrasion, ageing, ozone and oil resistant, outer thermoplastic helix

TECHNICAL CHARACTERISTICS

- Temperature range : -25°C / +80°C ( -13°F / +176°F )

- Norm : ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 38 | 1,50 | - | - | 0,9 | 13 | 10 | 150 | 30 | 450 | 1,17 | 0,78 | 80 | 3,15 |

| 51 | 2,00 | - | - | 0,9 | 13 | 10 | 150 | 30 | 450 | 1,57 | 1,05 | 100 | 3,94 |

| 63,5 | 2,50 | - | - | 0,8 | 11,5 | 10 | 150 | 30 | 450 | 1,90 | 1,27 | 130 | 5,12 |

| 76 | 3,00 | - | - | 0,8 | 11,5 | 10 | 150 | 30 | 450 | 2,30 | 1,54 | 150 | 5,91 |

| 102 | 4,00 | - | - | 0,7 | 10 | 10 | 150 | 30 | 450 | 2,97 | 1,99 | 200 | 7,87 |