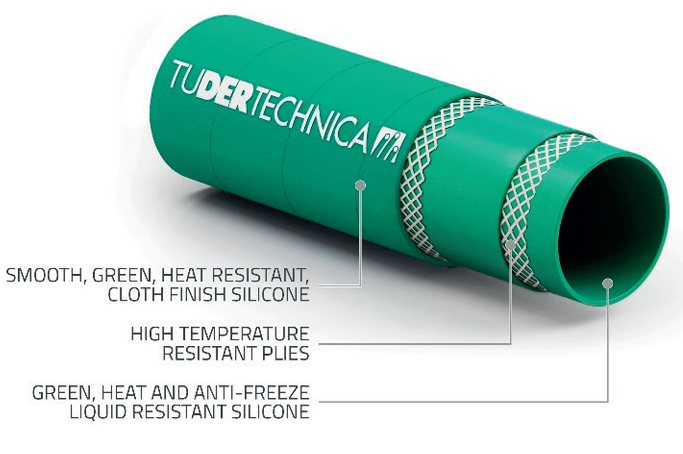

Straight connection between radiator and engine. Temperature range: -60°C / +200°C ( -76°F / +392°F ).

DESCRIPTION

- Tube : silicone, green, heat and anti-freeze liquid resistant

- Reinforcement : high temperature resistant plies

- Cover : smooth, silicone, green, abrasion, ageing, ozone and heat resistant, cloth finish

- Marking : TUDERTECHNICA TUSIL® RAD

TECHNICAL CHARACTERISTICS

- Temperature range : -60°C / +200°C ( -76°F / +392°F)

- Norm : SAE J20R1 CLASS A TMC RP303B ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 10 | 0,39 | 18 | 0,71 | - | - | 20 | 300 | 60 | 900 | 0,20 | 0,13 | - | - |

| 13 | 0,50 | 21 | 0,83 | - | - | 19 | 285 | 57 | 855 | 0,24 | 0,16 | - | - |

| 16 | 0,63 | 24 | 0,94 | - | - | 17 | 255 | 51 | 765 | 0,29 | 0,19 | - | - |

| 19 | 0,75 | 29 | 1,14 | - | - | 13 | 195 | 39 | 585 | 0,45 | 0,30 | - | - |

| 25 | 1,00 | 35 | 1,48 | - | - | 11 | 165 | 33 | 495 | 0,56 | 0,38 | - | - |

| 32 | 1,25 | 42 | 1,65 | - | - | 9 | 135 | 27 | 405 | 0,70 | 0,47 | - | - |

| 38 | 1,50 | 48 | 1,89 | - | - | 7 | 105 | 21 | 315 | 0,81 | 0,54 | - | - |

| 51 | 2,00 | 61 | 2,40 | - | - | 6 | 90 | 18 | 270 | 1,05 | 0,79 | - | - |

| 63,5 | 2,50 | 73,5 | 2,89 | - | - | 5 | 75 | 15 | 225 | 1,28 | 0,86 | - | - |

| 76 | 3,00 | 86 | 3,39 | - | - | 4 | 60 | 12 | 180 | 1,52 | 1,02 | - | - |

| 102 | 4,00 | 112 | 4,41 | - | - | 3 | 45 | 9 | 135 | 2,01 | 1,35 | - | - |

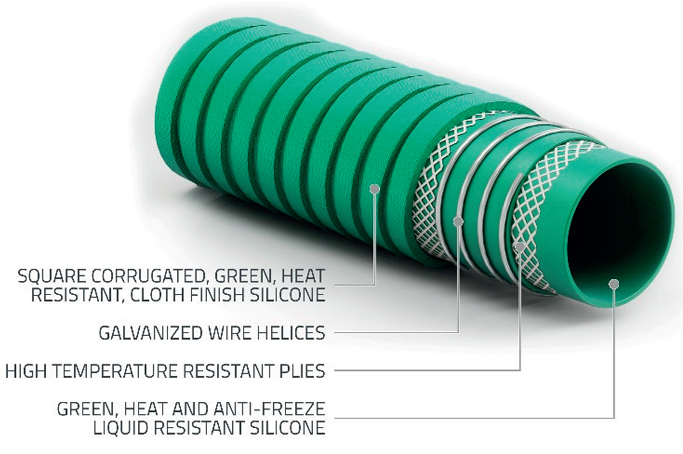

Tight bend connection between radiator and engine. Can be used to replace pre-formed elbows due to the highly flexible structure. Temperature range: -60°C / +200°C ( -76°F / +392°F ).

DESCRIPTION

- Tube : silicone, green, heat and anti-freeze liquid resistant

- Reinforcement : high temperature resistant plies, galvanized wire helix

- Cover :square corrugated, silicone, green, abrasion, ageing, ozone and heat resistant, cloth finish

- Marking : TUDERTECHNICA TUSIL® RADFLEX

TECHNICAL CHARACTERISTICS

- Temperature range :-60°C / +200°C ( -76°F / +392°F)

- Norm : SAE J20R1 CLASS A TMC RP303B ISO 1307 for dimensional tolerances

| Inside diameter | Outside diameter | Vacuum | Working pressure | Burst pressure | Appr. weight | Bending radius | |||||||

| [mm] | [in] | [mm] | [in] | [bar] | [psi] | [bar] | [psi] | [bar] | [psi] | [kg/mt] | [lbs/ft] | [mm] | [in] |

| 13 | 0,50 | 23 | 0,91 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 0,31 | 0,21 | 30 | 1,18 |

| 16 | 0,63 | 26 | 1,02 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 0,37 | 0,25 | 40 | 1,57 |

| 19 | 0,75 | 29 | 1,14 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 0,42 | 0,28 | 50 | 1,97 |

| 25 | 1,00 | 35 | 1,38 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 0,53 | 0,36 | 65 | 2,56 |

| 32 | 1,25 | 43 | 1,69 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 0,79 | 0,53 | 85 | 3,35 |

| 38 | 1,50 | 49 | 1,93 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 0,92 | 0,62 | 105 | 4,13 |

| 51 | 2,00 | 64 | 2,52 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 1,48 | 0,99 | 150 | 5,91 |

| 63,5 | 2,50 | 77,5 | 3,05 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 1,97 | 1,32 | 220 | 8,66 |

| 76 | 3,00 | 92 | 3,62 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 2,56 | 1,72 | 270 | 10,63 |

| 102 | 4,00 | 119 | 4,69 | 0,6 | 8,5 | 5 | 75 | 15 | 225 | 3,70 | 2,48 | 400 | 15,75 |